Cymbal Selection

Cymbal selection is another important element of kit-building that affects a drummer’s sound. The first step in selecting your new cymbal is knowing the different construction techniques and how they affect tone and projection. The second step is knowing how to test cymbals to determine which ones are right for you.

Overall, the differences in the price of cymbals is directly related to the amount of work that is put into making the instrument.

Cast cymbals are individually poured and cast from raw, molten metal. the castings are then put through a complex sequence of heating, rolling, shaping, hammering, and lathing. This labor-intensive process results in greater projection, clarity and durability than non-cast cymbals. They also have a rich, full-bodied sound that improves with age.

Sheet cymbals, or “non-cast”, begin as pre-formed disks cut from large sheets of rolled metal with a uniform thickness and alloy mixture. These cymbals are then hammered and shaped, giving them various sonic characteristics. Because they re cut from the same roll, sheet cymbals have uniform sound and tone within each model series. They have a very fast response and quick decay.

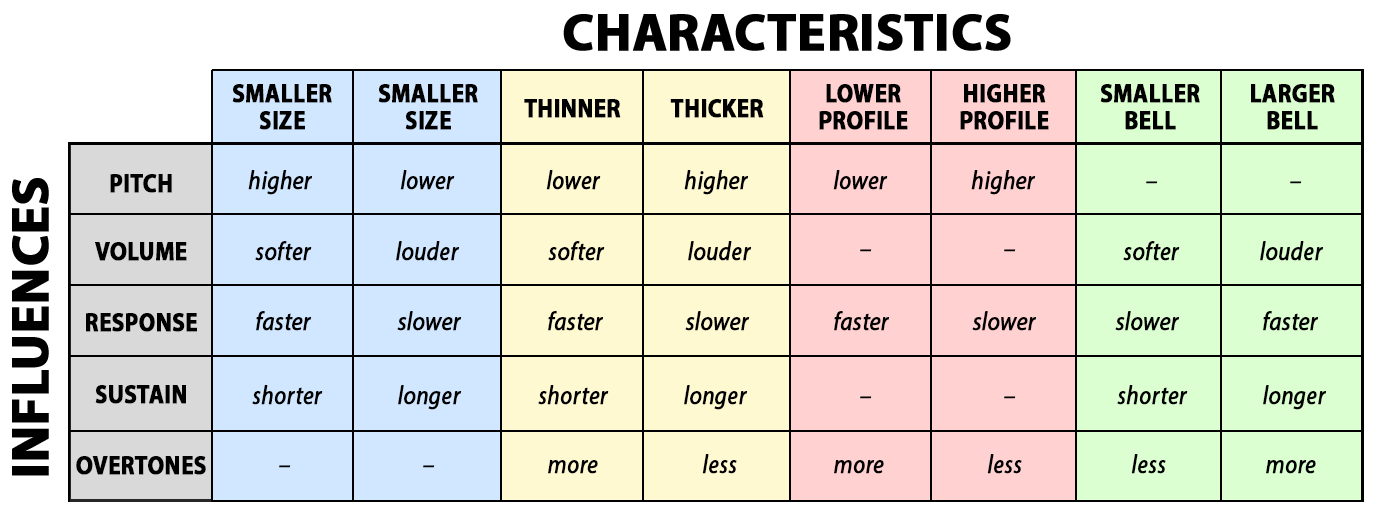

Whether it is cast or sheet, a cymbal’s physical characteristic is perhaps more important to its sound than the process that’s used to make it. The chart below illustrates some of these characteristics and their sonic influences. Manufacturers combine these various parameters to produce a wide spectrum of cymbals, providing you with the tools you need to create your own signature sound.

The most important step in cymbal selection is the actual testing of cymbals. It’s a bit of an art form. To begin, it’s a good idea to bring your other cymbals with you to the store, because ultimately your new cymbal must work harmonically as part of a set. Otherwise you’ll end up with just a random collection of sounds. Also, the influence of room acoustics is diminished when you include cymbals with sounds you are familiar with as a reference. Of course, the best way to test cymbals is to mount them on a kit.

As a rule, low frequencies give a cymbal its body; higher frequencies give it projection. But your audience will not perceive the lowest frequencies. They will hear the highs, which is ultimately responsible for a cymbal’s effective sustain and decay characteristics.

If you want to hear a cymbal’s entire frequency range clearly, roll the cymbal softly with timpani mallets. This will remove the harsh influence of the stick attack, allowing you to hear all the tone and sound a given cymbal will produce.

Generally, the interval between the notes you hear near the cup ought to be in harmony with the lower notes you hear near the edge of the cymbal. This will give you a cymbal that will be in tune with itself, no matter where you hit it.